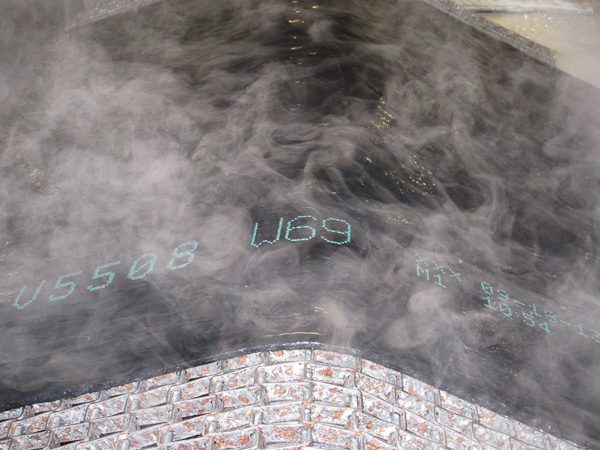

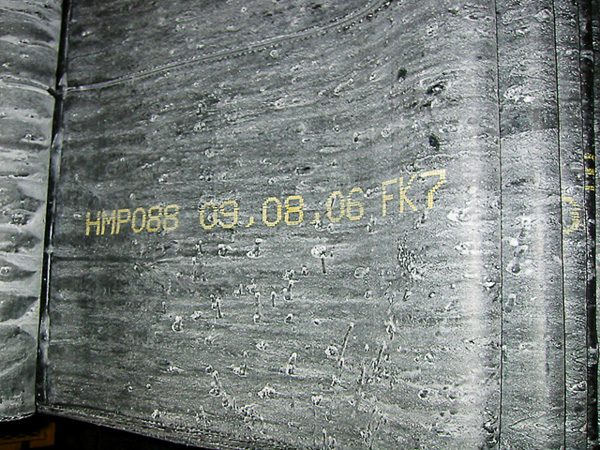

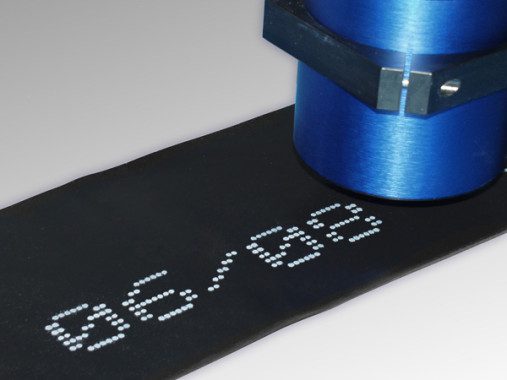

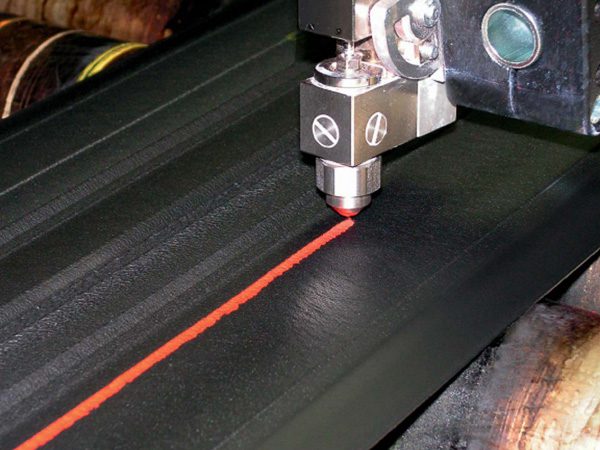

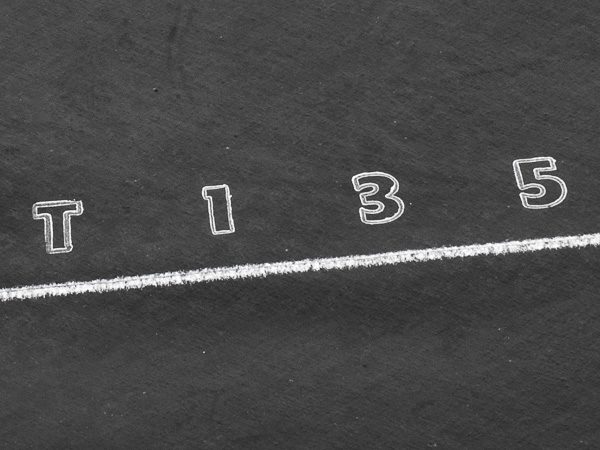

Being able to precisely identify and isolate product defects eliminates the need to scrap entire batches of material. The use of automated marking systems eliminates marking errors and enables real-time production information to be imprinted on products before and after curing.

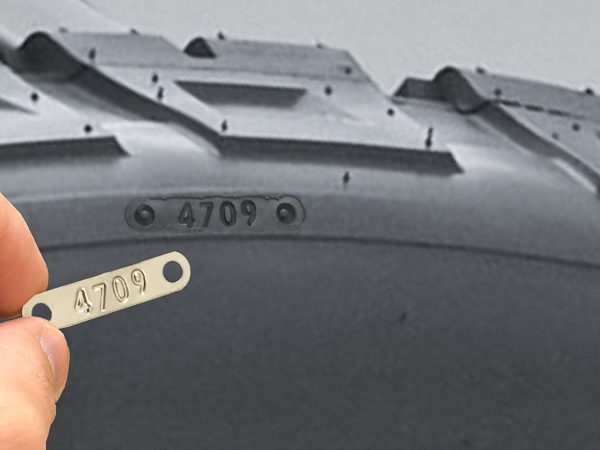

Meet DOT traceability requirements easily with the right marking system for your application. The use of indent markers, embossed tags, and laser marking systems enables molded rubber products to carry identification for their entire useful lives.