Fast and easy to program with the Universal AC500 Controller

The AC500 controller features a 7″ color touchscreen display for easy programming, crash-proof Linux-based software, and 64MB of internal flash memory to store hundreds of marking programs.

The AC500 can be used with any Automator ADP marking system as well as dot peen systems made by other manufacturers. This makes it easy to create and manage files on multiple systems in your facility. The AC500 software can also be installed on a PC for management of marking patterns and settings – files can be uploaded and downloaded via the USB port.

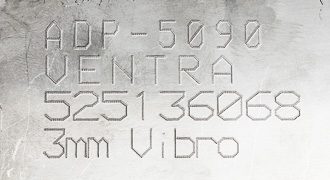

Marking Pin Options

Marking pins are available in different sizes to achieve different marking styles and depths.

All Automator ADP marking heads can operate in Dot Peen or Vibropeen marking mode. Simply change the pin assembly and adjust the head settings.

Find the right size head for your marking jobs.

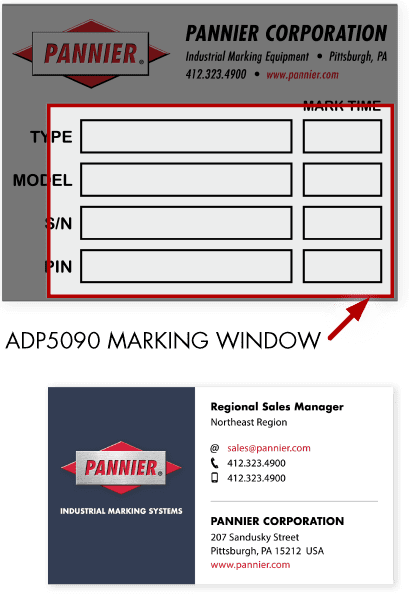

The marking window represents the maximum allowable marking area for each head. For example, the ADP5090 marking head’s window size is 50 mm x 90 mm, about the size of a business card.

Choose a marking window that corresponds with the mark you want to make, which in many cases does not equal the size of the item being marked, as shown in the example here.

Marking Head Sizes

| Head | Marking Window Dimensions | Overall Head Dimensions | ||

|---|---|---|---|---|

| ADP2560 | 25 x 60 mm | 1″ x 2.4″ | 139 x 82 x 167 mm | 5.5″ x 3.2″ x 6.6″ |

| ADP25120 | 25 x 120 mm | 1″ x 4.7″ | 199 x 80 x 167 mm | 7.8″ x 3.2″ x 6.6″ |

| ADP5090 | 50 x 90 mm | 2″ x 3.5″ | 180 x 150 x 121 mm | 7.1″ x 5.9″ x 4.8″ |

| ADP120160 | 120 x 160 mm | 4.7″ x 6.3″ | 260 x 220 x 123 mm | 10.2″ x 8.7″ x 4.8″ |

| ADP120160D | 120 x 160 mm | 4.7″ x 6.3″ | 260 x 220 x 169 mm | 10.2″ x 8.7″ x 6.7″ |

| ADP300400 | 300 x 400 mm | 11.8″ x 15.7″ | 514 x 424 x 148 mm | 20.2″ x 16.7″ x 5.8″ |

| ASM6090 | 60 x 90 mm | 2.4″ x 3.5″ | 200 x 170 x 194 mm | 7.9″ x 6.7″ x 7.6″ |

| ASM40150 | 40 x 150 mm | 1.6″ x 5.9″ | 360 x 200 x 207 mm | 14.2” x 7.9” x 8.1” |

Integrated

Incorporate marking into your automated production line.

Mount a marking head on a robot or slide and actuate the marking cycle remotely.

Protective shutters keep dust and dirt out.

Benchtop

Choose a complete, self-contained marking station for the factory floor.

Mount a marking head on a heavy-duty tool stand.

The slotted base accommodates various workholding fixtures for marking your parts.

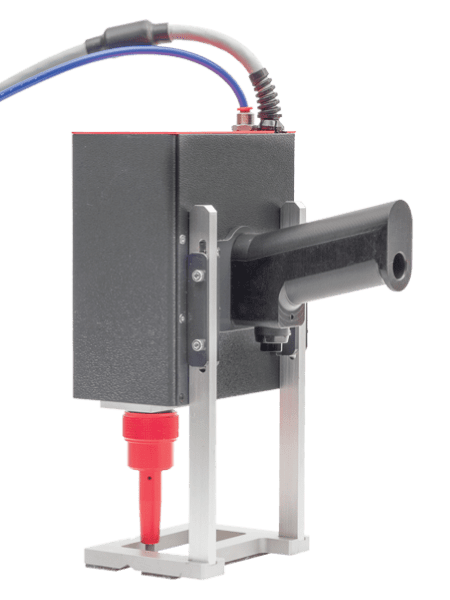

Portable

Stamp large parts with a hand-held marking system.

Choose from several standard models or let Pannier help you design a custom system for your needs.

An integrated pushbutton actuates the marking cycle.

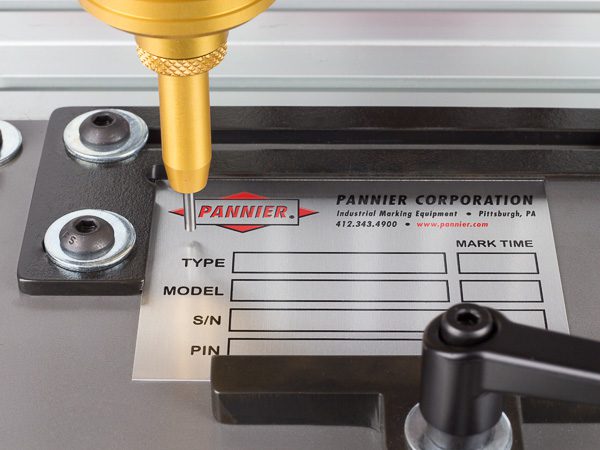

Tag & Plate

Fast, automated marking of metal tags and nameplates.

Choose a plate engraving system designed to hold your existing plates or a high-volume tag production system.

Take data management to the next level with Pannier software solutions.