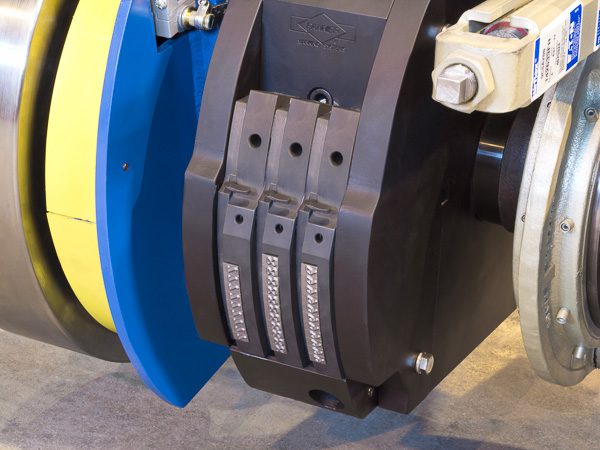

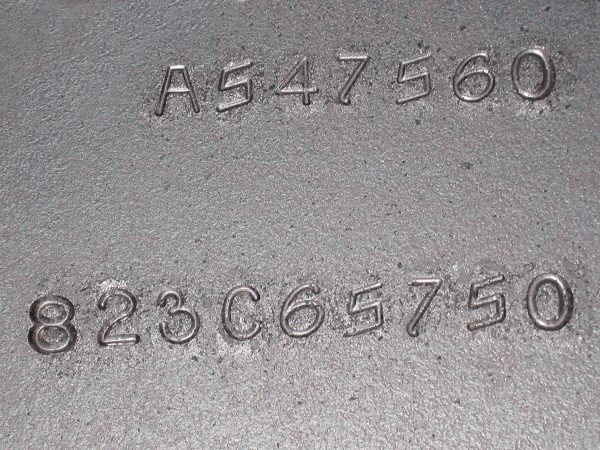

The Rotary Plate Stamper is specially designed to mark multiple lines of customer information on moving steel plate in heavy-duty mill environments. The marking sequence can be varied with plate length by setting the length and number of cuts on thumb-wheel switches.

- Marking wheel uses long lasting, high quality type supported in a quick-change holder

- Mounting structure safely moves the marking wheel off-line for legend changing and maintenance

Stamper Operation

During the stamping operation, the surface speed of the stamping wheel is synchronized with the speed of the plate by a friction drive between the plate and the drive wheels. The drive wheels are in constant contact with the plate, and the marking wheel is actuated by a PLC signal. When the entire plate has been stamped, the marking wheel raises automatically; a manual stamping mode may be used to make additional marks on long plates.