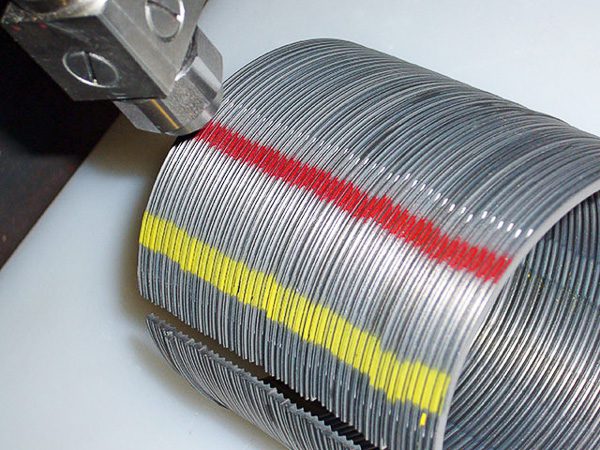

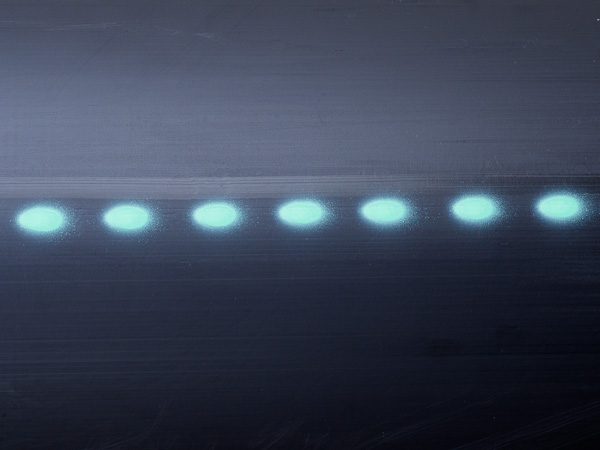

The ST Spray Marker is a revolutionary marking product for industrial coding applications. Dot, stripes, and patterns can be easily printed by sending signals to the solenoid valve manually or with a PLC. With extremely short cycle times of 20 milliseconds, print speeds of up to 100 meters/minute (325 feet/minute) are easily possible. The dot size is controlled by the size nozzle used, and adjustment of the material pressure and head settings.

Designed for maximum uptime.

The ST Spray Marker sets itself apart from other systems because of its simplicity of use, low maintenance needs, and excellent repeatability of high quality marks in any mounting direction. The compact design allows for trouble-free integration into nearly any production environment. Designed to apply fluids without the clogging problems typical of other ink marking systems, the ST provides an unparalleled level of reliability for color coding and inspection marking in a variety of manufacturing applications.

- All-metal spray heads use nozzle sealing technology to prevent clogs

- Integrated cleaning function ensures immediate operating readiness

- Components are easily switched out for maximum system uptime

Build Options

The front and rear of the heads are available in stainless steel, nickel-plated brass, or aluminum to accommodate different fluids, environmental requirements, and weight requirements.

Nozzle Sizes

Heads can be supplied with different nozzles to achieve the ideal dot or stripe size for your coding application. Available nozzle sizes are 0.3, 0.5, 0.8, 1.0, 1.2, and 1.5 mm.

Use a variety of ink types and colors for marking porous and non-porous materials such as metals, plastics, and textiles.

- Solvent based, alcohol, acetone, and MEK inks

- Bright pigmented inks

- Water based inks

- High temperature paints

- Special and customized inks