3D Laser Marking with Autofocus

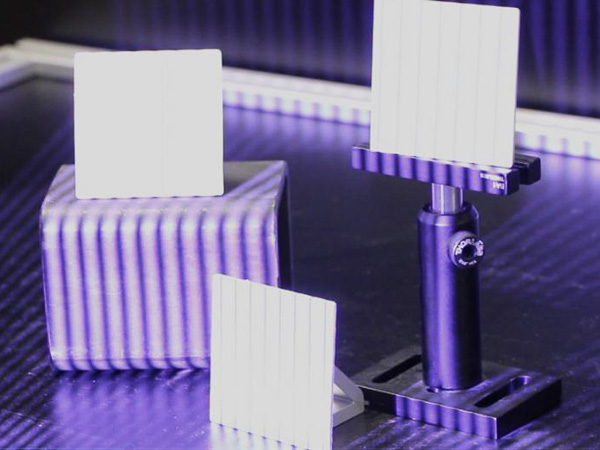

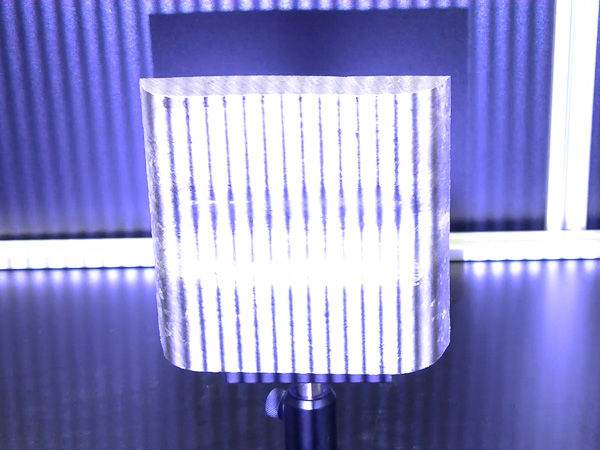

Laserax LXQ-3D Vision laser marking systems use an integrated auto-focusing system that automatically adjusts the marking job to the position and geometry of the part. Once the part surface is scanned, the data can also be used for quality control analysis. An integrated camera can be used for automatic bar code scanning and validation.

- Mark parts anywhere within the 12″ x 5.5″ marking area

- Industrial-grade cabinets withstand the most challenging environments

- Capable of marking metals at high temperatures

In addition to marking, the system also offers these capabilities:

- Remove rust, paint, oxidation, and other contaminants from metallic surfaces

- Detect part defects and avoid marking or flag the part as scrap

- Store scanned 1D and 2D codes with other parameters such as the date and time of the marking and confirmation that the code is read

| Wavelength | 1,064 nm |

|---|---|

| Laser Power Options | 20W, 30W, 50W, 100W, 200W |

| Safety Classification | Class 4 |

| Protection Class | IP65 to IP67 |

| Spot Size | ~ 50 µm to 100 µm, depending on configuration |

| Communication | Ethernet, RS-232, USB, digital input/output, encoder signal |

| Focal Distance | 18.1″ to 23.6″; factory set to 21.5″ 460 mm to 600 mm; factory set to 547 mm |

| Marking Window | 10.2″ x 10.2″ to 12.8″ x 12.8″ (factory set to 11.8″ x 11.8″) 260 mm2 to 324 mm2 (factory set to 300 mm2) |

| Mark on the Fly (MOTF) | No |

| Stand-alone Operation | Yes |

| Characters per second | Depends on application |

LXQ lasers can be supplied with a variety of automated safety enclosures for use as stand-alone workstations or inline marking cells. Control panels and enclosures for the laser source, controller, and optional cooling systems allows easy installation in all types of work environments.