A third-party logistics company (3PL) has implemented a system of using returnable containers made of…

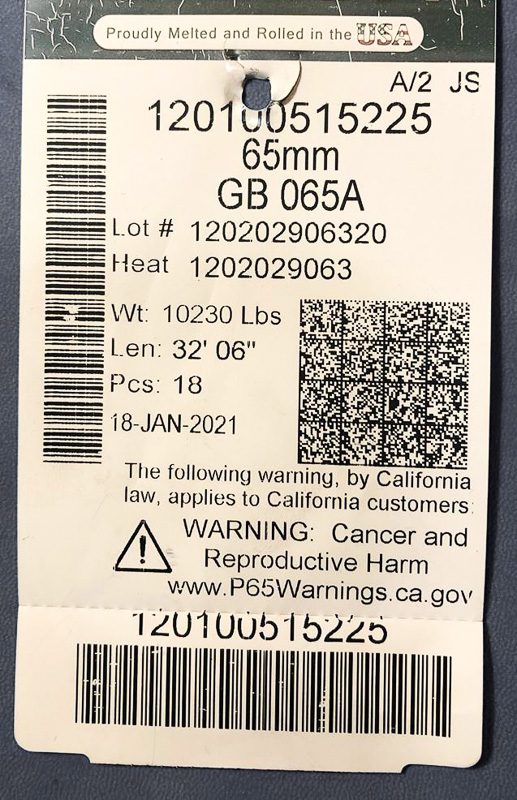

A manufacturer of specialty steel needed to find tracking tags for their unique manufacturing process involving long-term heat exposure. They make steel rod that is used to manufacture grinding balls in the mining industry. After the steel rod is formed it is immediately bundled and tagged while still hot, about 700-800°F. The bundles are then loaded into a large container where they can cool slowly, which imparts special characteristics on the steel. Temperatures here remain at about 500°F for three to four days.

They were pleased to find that Pannier PXL1100 tags survived not only the high initial temperature at the time of attachment, but also the extended heat exposure. Tags remain legible and securely attached, eliminating the need to relabel the material before shipping to their customers. Just one tag does it all.