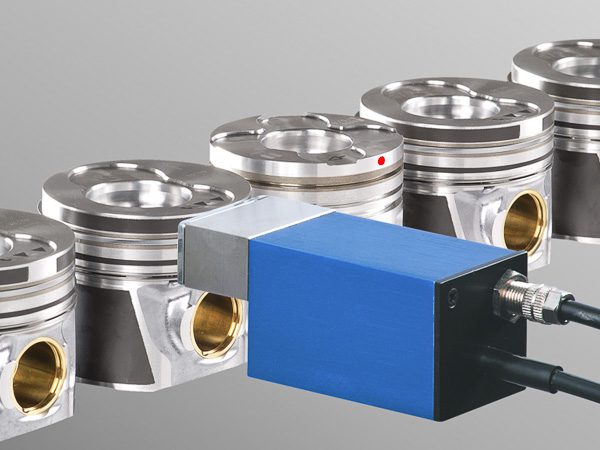

Ink jet dot printers are advanced alternatives to contact printers or spray systems for inspection marking, color coding, and placing location marks. These systems use ink jet technology to deliver clear and exact marks on any porous or non-porous material. The precise orifice sizes and dot size adjustments limit ink consumption and give you exceptional marking control.

- Mark dots from 1 mm to 6 mm wide

- Compact DOD ink jet marking head mounts in any orientation

- Patented design for reliable printing

- Print up to 700 dots/second

Ideal for Integration

The printers are designed to operate in harsh industrial environments such as high heat and humidity, and the print head is dustproof. If maintenance is needed, the quick-change modular components can be easily exchanged.

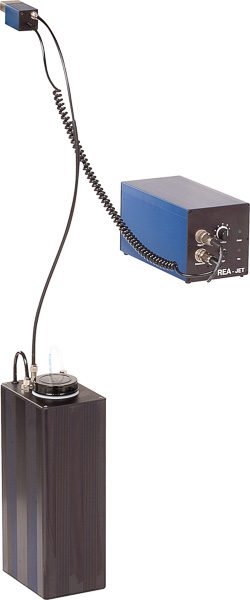

Printing can be triggered by a PLC, product sensor, or manual pushbutton control. A shaft encoder can also be used for variable-speed production lines.

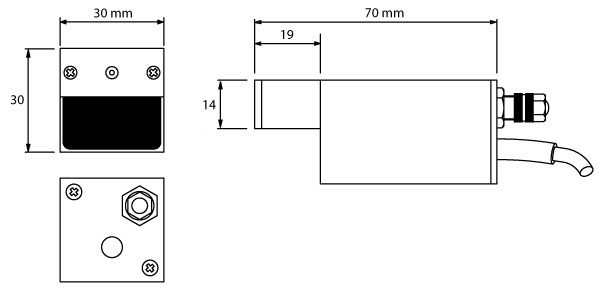

| Print Head Dimensions | 1.18″ sq x 2.75″ long | 30 mm x 30 mm x 70 mm |

|---|---|

| Mounting | top, bottom, or side |

| Operating Environment | 32°F to 113°F | 0°C to 45°C 10% to 90% non-condensing humidity |

| Electrical Supply | 115/230V AC; 50/60 Hz |

| Dot Size | .04″ to .24″ | 1 mm to 6 mm |

| Ink Supply | .5 gallon and 2.3 gallon | 2 liter and 5 liter |

| Head-to-Controller Cable | 3.3′, 10′, 20′, and 33′ lengths | 1 m, 3 m, 6 m, and 10 m |

| Controller Ports | I/O, product sensor, shaft encoder, Serial RS-232/422 (for setup) |

Dot Size Control

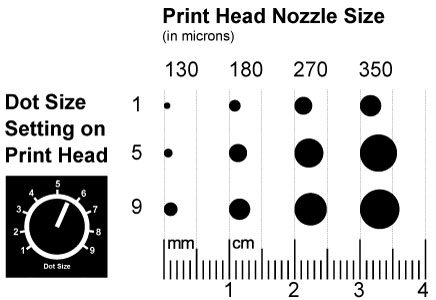

Print heads are available in different nozzle sizes for optimal ink usage.

The printer’s controller features a dot size control for adjusting the dot size without repositioning the print head.

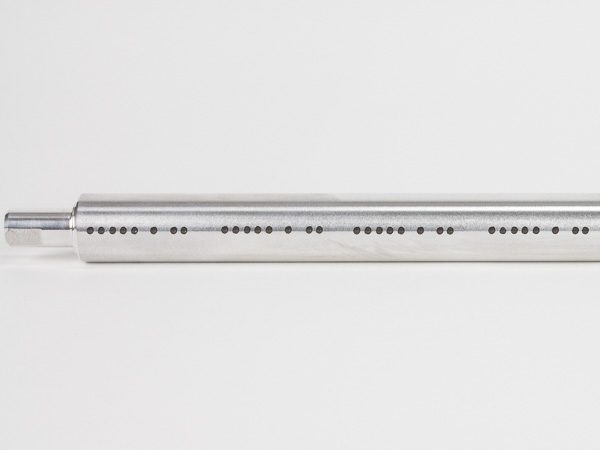

Print Patterns

The printer can be configured to mark single dots, continuous lines, or dot patterns.

Dot patterns can be programmed using any combination of dots and spaces. Different patterns can then be selected via a PLC. This enables labeling of different products or product states (e.g. good, poor, etc.) with different patterns. Thus only one system with one color ink may be required for product coding applications.

The pattern is programmed in the input line. An asterisk “*” represents a printed dot and an underscore “_” represents an empty place.

Example: *5_1*1_1*2_3 generates the print pattern shown below.

Different inks and paints give different results depending on the surface being marked and environmental factors. Mark opacity, adhesion, longevity, and drying time can vary widely. Sample marking your material in our lab ensures marking success.

- Solvent-based inks for excellent adhesion to non-porous surfaces

- High-speed drying acetone-based inks (VOC exempt)

- Water-based inks with no VOCs

- High-temperature inks

- Rubber co-curable inks