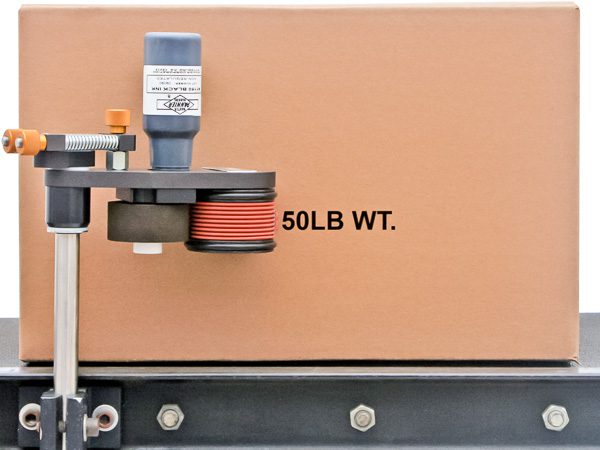

In-line code printers are a simple, economical solution for printing on moving materials. The printers use the friction of the passing items to trigger printing. Messages can be assembled on the print wheel using individual characters or logotypes (multi-character strips) for convenient message changing. As the print wheel rotates, ink is applied to the printing dies with an ink roll for clear and even printing.

- Quick-change printing dies and ink rolls for easy message and color changes

- Top or side mounting configurations can easily mounted to a shaft on a conveyor line

- Suitable for printing porous and non-porous materials at up to 700 feet/minute (210 meters/minute)

Indexing Models

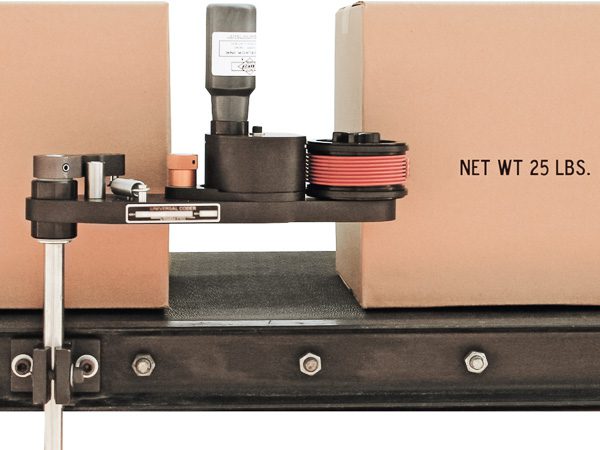

Indexing printers use a spring mechanism to return the print wheel to the same starting position after each mark is applied, placing the printed message in the same position on individual items. A small gap between each individual item is required for the printer to operate properly.

Non-indexing Models

Non-indexing printers rotate freely on their bearings and will stop at random positions when they disengage from the product being marked. These units are used for marking continuous materials.

| Printer | Indexing Models Available | Print Wheel Size (Message Repeat) |

Maximum Message Height |

|---|---|---|---|

| Mini-Coder | ✓ | 9.1″ 231mm |

2″ 51mm |

| Midsize Coder | ✓ | 12″ or 15″ 305 or 381mm |

2″ 51mm |

| Conveyor Line Printer | ✓ | 18″ 457mm |

4″ 102mm |

| Model CM-61 | 12″ 305mm |

3/4″ 19mm |

|

| Model 6076 | 12″, 18″, or 24″ 305, 457, or 610mm |

1″ 25.4mm |

Multiple Wheel Code Printers

Printers can be custom-built with multiple wheels for printing on products that require information to be printed on pre-determined centers. Mounting structures and programmable ink delivery systems make installation and operation easy.

For larger printing needs, see Pannier flexographic printers.