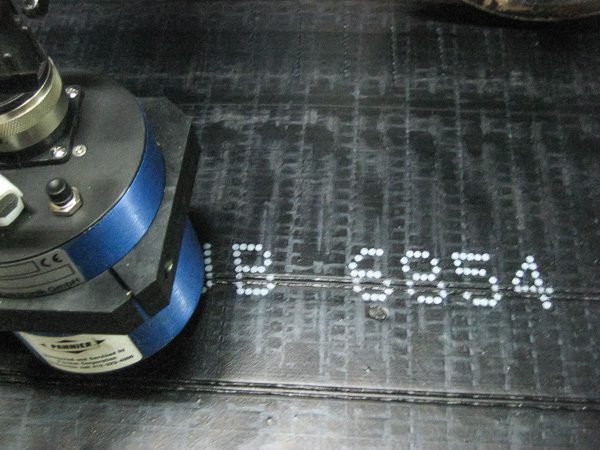

Industrial ink jet printing is an effective way to mark text, logos, 2D codes, and bar codes directly on moving materials. Since the printhead never touches the material being marked, ink jet printing can be used on a wide variety of surfaces without risk of marring or deforming the product. Printing on challenging materials is therefore made easy:

- Products with irregular (non-flat) surfaces

- Materials that are not rigid, such as extruded rubbers and plastics

- Products coated with paint, oil, or other surface protectants

Ink jet printers can be used as stand-alone units or receive and print data from a PLC or host system. This allows manufacturers to automatically print product information, date and time stamps, and even defect information immediately on their products.

Ink Printing Technologies Explained

Drop on Demand (DOD) Ink Jet Printers

Large Character Printing

DOD printheads feature several orifices arranged in a single column configuration. Electronic signals open and close one or more orifices at high speeds to allow droplets of ink to come out, forming characters, logos, and 2D codes in a dot matrix configuration.

DOD printers are also referred to as large-character ink jet printers: REA JET DOD printers can print character sizes from 1/4″ to 5-1/2″ (5mm to 140mm) high.

Thermal Ink Jet (TIJ) Printers

Small Character Printing

TIJ printers use HP ink jet technology in an industrial printer configuration. Each printhead cartridge contains the nozzles, the ink, and the electronic components needed to print messages. Ink fills each of the small nozzles in the printhead. Resistors in each nozzle heat the ink to release it from its chamber.

The entire cartridge is changed once the ink is depleted. Since the printhead nozzles and electronics are new with every cartridge, this results in a printing system that requires no maintenance or repairs.

TIJ printers are referred to as small-character ink jet printers, forming tiny characters up to a maximum of 2″ (50.8 mm) high.

Continuous Ink Jet (CIJ) Printers

Small Character Printing

Ink is continuously streamed through a single nozzle in the printhead and then broken into tiny droplets at a rate of 76,800 per second. Drops are selectively charged and deflected through a magnetic plate to produce characters, graphics, bar codes, and 2D codes.

CIJ printers are also referred to as small-character ink jet printers, forming characters from .08″ to .47″ (2mm to 12mm) high.

REA JET Industrial Ink Jet Printers

What makes REA JET printers different?

Pannier Corporation recommends and offers REA JET ink jet printers because they are suited for use in harsh industrial applications. REA JET DOD and TIJ systems are simple to operate and maintain, providing reliability and long-term value compared to more common CIJ printers.

REA JET ink jet printers are designed and manufactured in by REA Elektronik GmbH in Germany. With over 50,000 systems installed worldwide, they are are trusted, proven printing systems used in a wide variety of industries.

- REA JET printheads are ruggedly built for use in environments with dust, heat, fluids, and other contaminants that make printing challenging.

- Systems are modular, meaning components can be quickly swapped out for cleaning or replacement. This results in minimal downtime in high-speed manufacturing operations.

- The printheads can use specialty inks that can be problematic in other ink jet printers such as rubber-based tire marking inks and high-contrast pigmented inks for printing on metals.

- DOD and TIJ systems are self-serviceable, eliminating the need for the costly service contracts and backup systems required with CIJ printers.

- REA JET TITAN controllers are suitable for fast integration into plant systems.