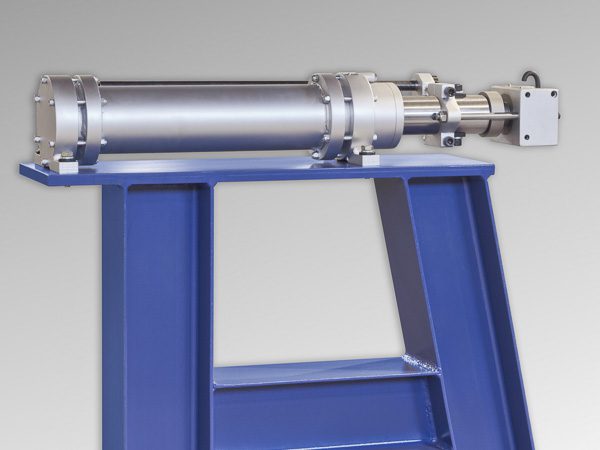

MarkFirst™ pneumatic stamping machines are heavy duty marking systems for metal products such as billets, rails, and castings. Easily installed and operated, these marking machines are built to withstand years of continuous use in mill and foundry environments.

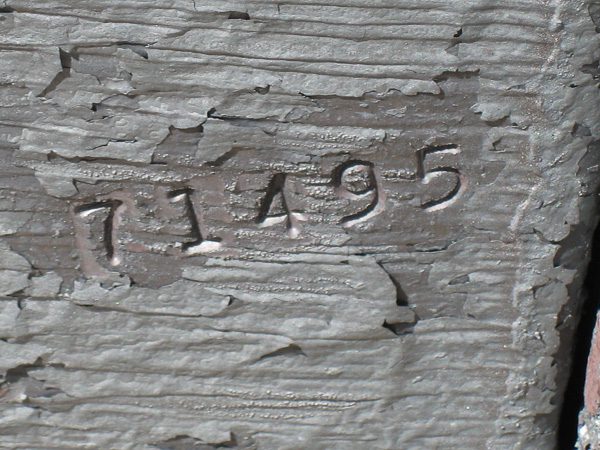

Clear, legible marking on hot or cold metals.

Type cartridges hold up to three lines of characters for marking information such as heat, strand, and grade numbers in one stroke. A “floating” anvil inside the marking head allows the characters to align with uneven or skewed surfaces (up to 5°) to ensure legible marks. Operators can quickly change messages by switching quick-change type cartridges between production runs.

Stationary Marking

The Model 9200 can be mounted horizontally or vertically on the production line. When the product being marked is in position, the marking cycle can begin. The air cylinder extends the marking head to make contact with the material, which actuates the stamping action.

Manual Marking

The Models D5 and F4 are lighter and suitable for mounting on a sling or a track with wheels. This makes it easy for an operator to mark many items in a short period of time.

| Specifications | Model D5 | Model F4 | Model 9200 |

|---|---|---|---|

| Stamping Force | 60 ft/lbs | 120 ft/lbs | 135 ft/lbs |

| Anvil Size | 2-1/2″ | 3-5/8″ | 2-1/2″ or 3-5/8″ |

| Length, Retracted | 44.9″ | 48.6″ | 36.5″ |

| Length, Extended | 45.6″ | 49.1″ | 50.5″ |

| Mounting Options |

|

|

|

| Weight | 60 lbs | 108 lbs | 120 lbs |