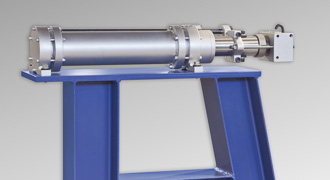

MarkFirst™ automatic marking machines make inline part marking fast and easy. Consistent, controlled-depth stamping is accomplished on the production line for reliable part numbering, branding, and serial numbering applications.

- Mark multiple characters in one stroke

- Mount in any direction

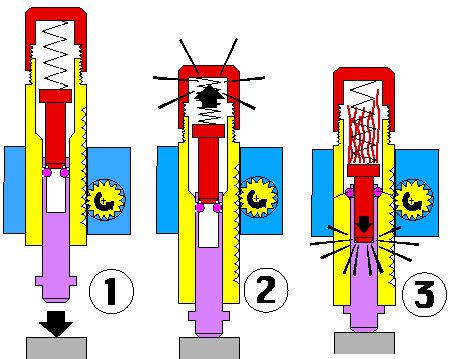

- Mark depth is easily controlled by adjusting the impact spring

- Interchangeable type holders allow for fast mark changes

These pneumatic machines are actuated using a solenoid valve or two-hand safety button switches. The cylinders are double-acting, requiring air to be supplied for both the stamping and return strokes. A four-way pneumatic valve is required for activation.

Calculate the pounds of force required per character:

| Character Size | Annealed Brass | Annealed Aluminum | Low Carbon Steel | Medium Carbon Steel | Cast Iron Alloy | Stainless Steel (300 Series) |

|---|---|---|---|---|---|---|

| 1/16″ (1.6mm) | 200 | 200 | 340 | 400 | 400 | 445 |

| 3/32″ (2.4mm) | 400 | 400 | 680 | 800 | 800 | 890 |

| 1/8″ (3.2mm) | 600 | 600 | 1,020 | 1,200 | 1,200 | 1,300 |

| 5/32″ (4.0mm) | 1,000 | 1,000 | 1,700 | 2,000 | 2,000 | 2,200 |

| 3/16″ (4.8mm) | 1,400 | 1,400 | 2,400 | 2,800 | 2,800 | 3,100 |

Example: Marking six 1/8″ characters into low carbon steel: 1,020 X 6 = 6,120 pounds of force required. The Model MB-21VP can be used, as it can apply a maximum of 7,700 pounds of force.

Get More Information

Talk to a marking specialist about this product.