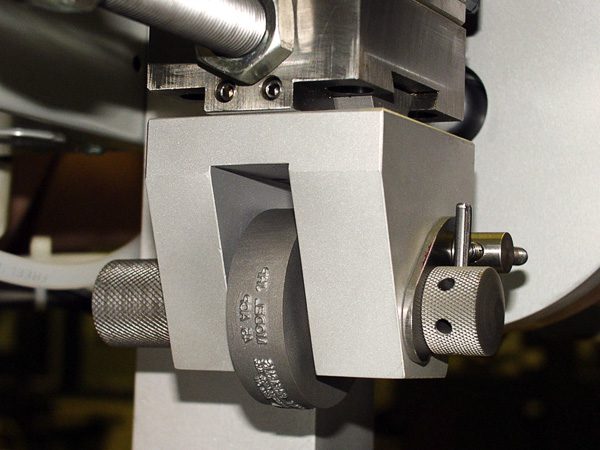

Roll marking machines offer a fast and efficient method of permanently marking either round or flat parts. Consistent, high-quality marks are made by rolling hardened dies into the part one character at a time, exerting minimal pressure on the part.

- Low stress marking method uses less force than other types of marking

- Deeper marking can be achieved by repeating the marking cycle multiple times

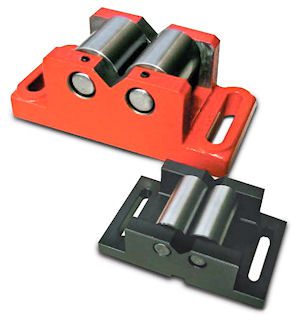

- Mark thin-walled material without distorting the part with the use of a mandrel support

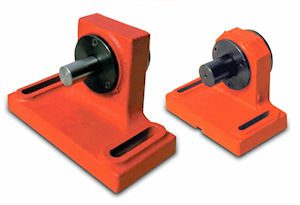

Round Products

Mark round parts up to 40″ in diameter.

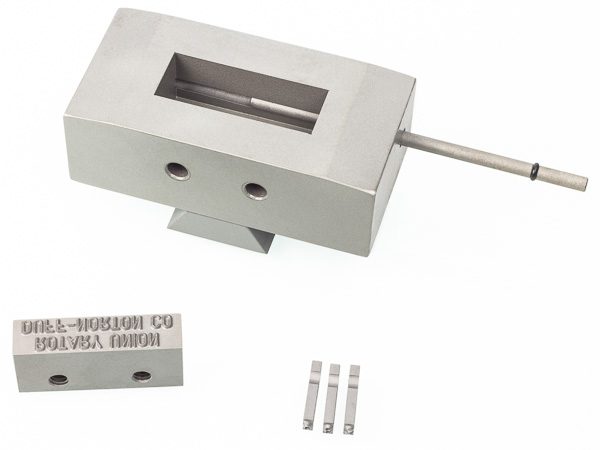

Flat Products

Mark flat parts with messages up to 7″ long.

41 Series Models

Mark round parts .315” to 2.5” in diameter (8mm to 65mm).

71 Series Models

Mid-size marking systems capable of marking rounds or flats. The working tables are fitted with spring washers to even out differences in diameter and to achieve consistent mark depth.

- mark rounds up to 4.3″ diameter (110mm)

- mark flats with messages up to 7″ long (180mm)

- 6.7″ x 6.3″ (170mm x 160mm) working table features 10mm T-slots to accommodate a variety of part holding fixtures

- use the adjustment wheel to set the proper height of the working table to mark your part