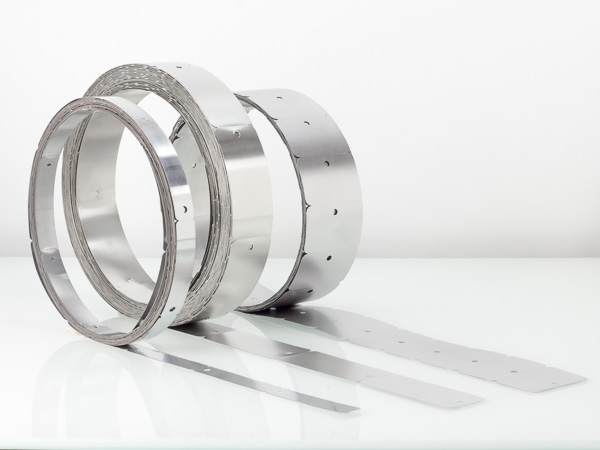

The EmbossMax 5000 automatic metal tag embossing machine is designed for medium- to high-volume tagging needs. A coil of pre-fabricated metal tags is loaded into the system and it’s ready to accept data and start embossing. Tags can be made in batches or individually and are then snapped apart for use.

- Emboss one or more lines of text, logos, and 2D Data Matrix codes

- Designed for continuous, jam-free marking of up to 1,000 tags per coil

Fully Automated Embossing

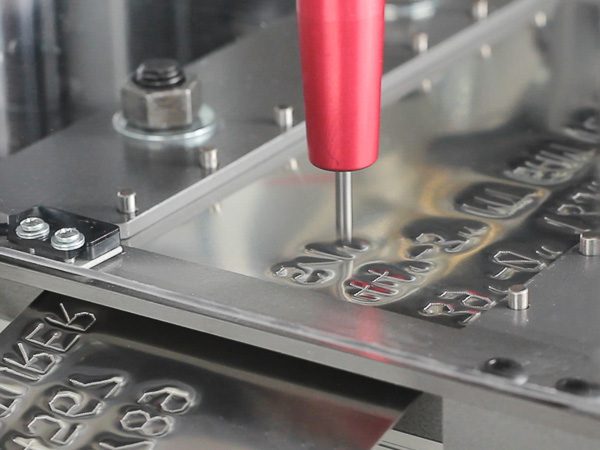

The EmbossMax 5000 uses dot peen technology to emboss metal tags using a carbide marking pin. The tag stock advances automatically after each tag is made. An optional recoiler can recoil the tags for later use.

Data to be marked can be loaded from a file or sent from a host system on your network. Make individual tags as needed via manual data entry or by scanning bar codes on job paperwork. Automatic data checking parameters can be set to prevent data entry errors.

Pannier manufactures metal tags to your specifications.

| Typical Tag Sizes | Thickness | .008″ to .018″ | .203mm to .457mm |

|---|---|---|---|

| Width | 7/8″, 2″ or 3″ | 22.225mm, 50.8mm, and 76.2mm | |

| Length | 1″ to 7″ (in increments of 1/8″) |

25.4mm to 177.8mm (in increments of 3.2mm) |

|

| Tag Materials | aluminum, steel, electro-galvanized steel, stainless steel | ||

| Hole Options | pre-fabricated holes or slots for easy attachment with tag clips or wire | ||

| Marking Options |

|

||

| Pre-Embossing |

Tags can be supplied pre-embossed with information such as your company name, logos, or field names (e.g. Grade, Weight, Customer, etc) for faster tag creation. |

||

Tagging Products in Harsh Industrial Processes

The raised characters on embossed tags remain legible through processes like shot blasting, pickling, annealing, hot dip galvanizing, painting, and powder coating where any other tag or label would be rendered unreadable. Your product identification remains intact even after years of exposure to outdoor conditions.